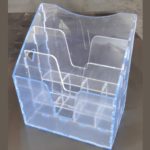

Product design

In laser operation, product design plays the most critical part of making the product industry ready. We need to keep many aspects in mind such as Material, Specifications, accuracy, curves and its utilization, use cases and various other factors as well. The marking outcome depends principally on the laser wavelength selected and the interaction time (pulse time) between the beam and the material. Metals, plastics, ceramics, glass, rubber, organic materials such as leather, wood and fabric, etc. Kaizen Formac LLP can help you choose the best solution for your application!

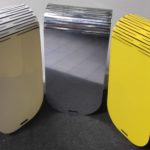

Trimming

Our lasers are ideal for trimming, cutting and etching parts with intricate designs that would be too expensive or difficult for mechanical punch tooling, especially for products under development. In many cases we laser trim prototype parts because it reduces the time and cost involved with trim tooling. We are able to trim and etch formed parts if the contours are not too drastic, so please describe your trimming challenge to us!

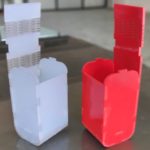

Engraving

Laser engraving is a laser supported, high-volume ablation process, which offers excellent opportunities for making high-precision printing, embossing, erosion, or injection tools. The great advantage over the conventional spark erosion technique consists in the fact that laser engraving is extremely flexible as to geometry and material. The laser engraves the material surface down to some 10 μm in depth. Laser engraved marks are exceptionally durable and can only be removed by heavy grinding. Therefore, laser engraving is used for forgery-proof product marking.

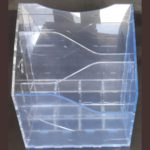

Mass Production

we at Kaizen have expertise in perfect proto typing and have industry experts and well experienced teams we can easily turn the prototype into a mass production and assembly. Prototyping may have many smaller imperfect processes which requires to be perfected in case of requiring

the mass production. Here the experience and expertise of Kaizen team comes into the picture.